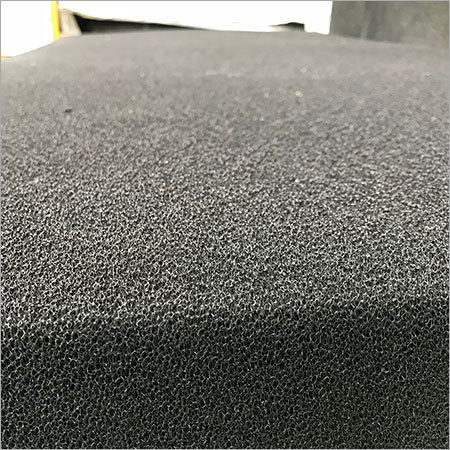

Industrial Reticulated Polyurethane Foam

Industrial Reticulated Polyurethane Foam Specification

- Material

- Reticulated Polyurethane Foam

- Texture

- Reticulated, Open Cell

- Product Style

- Industrial

- Characteristics

- High porosity, Lightweight, Flexible, Resilient, Washable, Chemical Resistant

- Application

- Filtration, Sound Absorption, Air and Water Filters, Gasketing, Cleaning Pads, Oil & Gas Separation

- Thickness

- 3 mm to 100 mm (customizable)

- Hardness

- 10-60 Shore A (custom depending on density and grade)

- Style

- Sheet, Roll, Die-cut shapes

- Shape

- Rectangular, Customized Shapes Available

- Color

- Black, Grey, Yellow, Blue (subject to availability)

- Packaging

- Bundled, Boxed or Customized

- Disposable

- Yes

- Size

- 300 mm x 300 mm, 500 mm x 500 mm, 1000 mm x 2000 mm or as per requirement

- Pattern

- Open Cell

- Tensile Strength

- >80 kPa

- Temperature Range

- -40C to +120C

- Odor

- Odourless

- Density

- 1824 kg/m (standard range)

- Water Absorption

- Low, rapid drainage

- Flame Retardancy

- Available on request (conforms to UL94 standards)

- Compression Set

- < 10% at 50% compression for 22 hours at 70C

- Pore Size (PPI)

- 10 PPI to 80 PPI (Pores Per Inch)

- Customization

- Shape, Size, Color, and Density on Demand

- Export Market

- Global

- Elongation at Break

- >150%

Industrial Reticulated Polyurethane Foam Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 3000 Pieces Per Day

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- As per customers requirement

- Main Domestic Market

- Delhi

- Certifications

- ISO 9001:2015 TUV SUD

About Industrial Reticulated Polyurethane Foam

Specification

- Product Name:- Reticulated Polyurethane Foam

- Color- Black

- Grade- Fire Retardant

- PPI- 15PPI, 20PPI, 25PPI, 30PPI

- Applications- Automobiles, Air conditioning, Bus ac & HVAC

Unmatched Filtration and Drainage Efficiency

With pore sizes from 10 to 80 PPI and open-cell construction, this reticulated polyurethane foam excels in air and liquid filtration, ensuring rapid drainage and low water absorption. Its customizable porosity tailors solutions for specific filtration requirements in industrial processes.

Engineered for Durability and Versatility

Manufactured to withstand harsh conditions, the foam exhibits high tensile strength, elongation at break, and a low compression set. Its resilience and chemical resistance make it suitable for environments demanding both flexibility and structural integrity, including gasketing and sound absorption.

Custom Solutions for Industrial Applications

Available in various sizes, densities, and colors, the foam can be cut or formed into sheets, rolls, or custom shapes. Whether used for cleaning pads, filtration units, oil separation, or packing, its reusability and adaptability meet global industry standards and client-specific needs.

FAQs of Industrial Reticulated Polyurethane Foam:

Q: How is the pore size (PPI) of reticulated polyurethane foam selected for different industrial applications?

A: The pore size, measured in pores per inch (PPI), is chosen based on the applications filtration or flow requirements. Lower PPI (10-30) offers larger pores ideal for bulk filtration or sound absorption, while higher PPI (60-80) is preferred for fine filtration or delicate cleaning tasks.Q: What customization options are available for this industrial foam product?

A: Shapes, sizes, densities, and colors can all be customized according to specific project needs. The foam is available in standard sheets, rolls, and die-cut forms, with bespoke thickness, hardness, and dimensions offered on demand to fit unique industrial applications.Q: When is flame-retardant foam recommended, and does it meet industry safety standards?

A: Flame retardant foam is recommended when the application requires compliance with fire safety regulations or when exposure to heat sources is expected. Upon request, the foam is manufactured to conform to UL94 flame retardancy standards, ensuring reliable fire resistance.Q: Where can this reticulated polyurethane foam be used effectively?

A: This foam finds application globally in air and water filtration units, sound dampening systems, sealing and gasketing, cleaning pads, and oil and gas separation. Its adaptability in both form and function supports industries like manufacturing, automotive, and environmental technology.Q: How does the foams open-cell structure benefit industrial processes?

A: The open-cell, highly reticulated design maximizes surface area and enables rapid fluid or air passage, making it ideal for filtration, drainage, and sound absorption. It also enhances the materials flexibility, resilience, and ability to be cleaned and reused efficiently.Q: Is the foam reusable or disposable, and how should it be maintained?

A: The industrial reticulated polyurethane foam is designed for reusability, with high resilience and washable properties. Regular cleaning helps maintain its filtration or absorptive performance, contributing to cost-effectiveness and sustainability in long-term industrial use.Q: What is the process for ordering customized foam solutions for export?

A: Clients can specify their requirements for size, thickness, density, hardness, and color. Orders are processed to match these details, and products are shipped globally in bundled, boxed, or customized packaging per client needs. Manufacturer support from India ensures timely delivery and consistent quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sponge Insulation With Oil Based Adhesive/ Gluing Category

Nitrile Roll With Adhesive

Shape : Roll

Pattern : Smooth

Size : Customizable per roll

Style : Industrialgrade

Product Style : Other

Texture : Other

Reticulated Polyurethane Foam

Shape : Rectangular sheet, block, or custom cut

Pattern : Reticulated (open cell network)

Size : Standard and custom sizes available

Style : Plain, customizable sizes and shapes

Product Style : Other, Sheet and block form

Texture : Other, Open cell, highly porous, spongelike

Nitrile Foam Rolls With Adhesive

Shape : Roll

Pattern : Plain

Size : Custom sizes available

Style : Industrialgrade adhesivebacked foam rolls

Product Style : Roll with adhesive, Other

Texture : Other, Smooth

Nitrile Tapes

Shape : Circular (rolls)

Pattern : Plain

Size : Custom sizes available

Style : Selfadhesive

Product Style : Tape, Other

Texture : Smooth, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS